In the world of industrial grinding and milling, efficiency is everything. Whether you're processing minerals, manufacturing paints, or creating advanced ceramics, the goal is to reduce particle size as effectively and economically as possible. While much attention is paid to the mill itself, the true unsung heroes are the grinding media—the balls, beads, or cylinders that do the actual work of impact and attrition.

Selecting the wrong grinding media can lead to catastrophic costs: excessive contamination that ruins a product batch, high wear rates that spike operational expenses, or inefficient grinding that wastes energy. This comprehensive guide will walk you through the critical factors for choosing the right grinding media—from steel and ceramic to specialized options—for your specific material and application.

Understanding the Key Selection Criteria

Before diving into material types, you must understand the variables that dictate the optimal choice.

1. Material Contamination: The Prime Consideration

This is often the most critical factor. How much media wear can your product tolerate?

High Contamination Sensitivity: Products like pharmaceuticals, food, dyes, cosmetics, and advanced ceramics require virtually zero metallic contamination. Ceramic or glass media is essential.

Low Contamination Sensitivity: In applications like primary ore grinding in mining, some iron contamination from steel balls is irrelevant to the final product and can be tolerated.

2. Material Hardness & Abrasiveness

The media must be harder than the material being ground to avoid rapid wear.

Hard, Abrasive Materials: (e.g., silica sand, granite, quartz) require extremely hard and wear-resistant media like high-chromium steel or ceramic alumina.

Softer Materials: (e.g., limestone, coal, talc) can use less expensive media like forged steel or cast iron balls.

3. Mill Type & Operating Parameters

The design of your mill dictates the size and density of the media you can use.

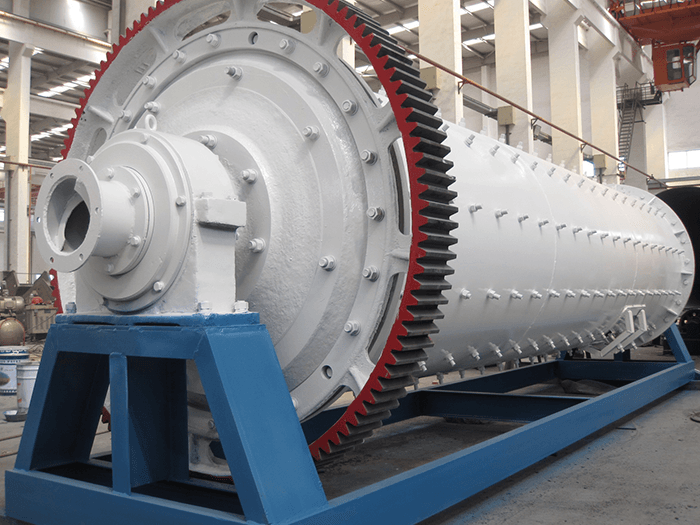

Ball Mills: Use larger media (e.g., 25mm-100mm balls).

Stirred Mills (Attritors) & Bead Mills: Use smaller media (e.g., 0.5mm-3mm beads).

Impact vs. Attrition: Larger, denser media are better for impact grinding (e.g., in a ball mill). Smaller, harder media are superior for attrition grinding (e.g., in a vertical mill) as they provide more contact points.

4. Grinding Efficiency & Specific Energy Consumption

Denser media transmits more energy per impact, often leading to more efficient grinding and lower energy costs. Steel is denser than ceramic, which is denser than glass. The goal is to find the densest media that doesn't compromise your product purity.

5. Cost & Wear Life

While ceramic media may have a higher upfront cost than steel, its incredible wear resistance in abrasive applications can make it far more economical over time. Always calculate the cost per ton of material ground, not just the initial media price.

A Guide to Grinding Media Types and Their Applications

Here’s a breakdown of the most common types of grinding media and where they excel.

1. Forged Steel Balls

Composition: Carbon and alloy steel heated and hammered into shape.

Density: High (~7.8 g/cm³). Excellent for impact grinding.

Pros: Very tough, resistant to spalling (chipping), good wear resistance, cost-effective for many applications.

Cons: Prone to corrosion (rusting), high iron contamination.

Ideal For: Primary grinding in mining (copper, gold, iron ore), cement manufacturing, and coal pulverization where contamination is not a concern.

2. High-Chrome Cast Steel Balls

Composition: Steel alloy with 10-18% chromium, cast into shape.

Density: High (~7.8 g/cm³).

Pros: Excellent hardness and wear resistance, more corrosion-resistant than forged steel.

Cons: More expensive than forged steel, can be brittle and fracture under impact if not high quality.

Ideal For: Abrasive applications where wear life is paramount. Common in cement plants and the mining industry for secondary grinding.

3. Stainless Steel Balls

Composition: Steel alloyed with chromium (and often nickel) for corrosion resistance.

Density: High (~7.8 g/cm³).

Pros: Highly corrosion-resistant, good for wet grinding, lower iron contamination than carbon steel.

Cons: Softer than high-chrome steel, leading to higher wear rates in abrasive applications. More expensive.

Ideal For: Food processing (e.g., grinding spices, chocolate), chemical applications, and pigment grinding where some metal contamination is acceptable but rust must be avoided.

4. Ceramic Grinding Media

This category includes several compositions, primarily Alumina and Zirconia-based.

General Pros: Chemically inert, non-corrosive, zero metallic contamination, high hardness.

General Cons: Lower density than steel, higher cost, can fracture under extreme impact.

a) Alumina Ceramic (68-90% Al2O3)

Density: Medium-High (~3.4-3.8 g/cm³).

Ideal For: A great general-purpose ceramic media. Perfect for grinding ceramics, glass, minerals, paints, and inks where iron contamination is prohibited. The workhorse of non-contaminating grinding.

b) Zirconia Silicate / Yttria-Stabilized Zirconia (YSZ)

Density: Very High (~3.8-6.0 g/cm³).

Pros: The hardest and most wear-resistant common ceramic media. Exceptional density (close to steel) offers high grinding efficiency.

Cons: The most expensive option.

Ideal For: High-performance, demanding applications: pharmaceutical nano-sizing, high-quality inkjet inks, advanced ceramics, and electronics materials. Used where maximum wear life and energy efficiency are critical.

5. Glass Beads

Density: Low (~2.5 g/cm³).

Pros: Inexpensive, chemically inert, good for certain low-contamination applications.

Cons: Low density and hardness lead to high wear rates and short life. Fragile.

Ideal For: Short-run, low-impact grinding in bead mills for paints, inks, and laboratory applications. A low-cost, disposable option.

Application-Specific Recommendations

Mining & Mineral Processing: Start with forged steel for primary grinding. Move to high-chrome steel balls for secondary grinding to maximize wear life.

Paint, Ink, & Dye Production: Use ceramic (Alumina or Zirconia) or glass beads in bead mills to prevent color contamination and achieve fine, consistent particle sizes.

Pharmaceuticals & Cosmetics: Yttria-Stabilized Zirconia (YSZ) is the gold standard for nano-grinding and milling active ingredients without metallic contamination.

Food Industry: Stainless steel is typical for many applications. For highly sensitive products or where even stainless steel is a concern, use ceramic media.

Cement Production: High-chrome cast steel balls are the industry standard due to the extremely abrasive environment and the need for long wear life.

Conclusion: A Process of Elimination

Selecting the right grinding media is a systematic process of elimination:

Start with Contamination: Is iron acceptable? If no, eliminate all steel media.

Consider Hardness & Abrasiveness: Match the media hardness to your material. Abrasive materials demand high-hardness media like high-chrome steel or zirconia.

Analyze Operational Costs: Calculate the total cost of ownership, including media consumption rate, energy efficiency, and downtime for media changes.

There is no universal "best" grinding media—only the best for your specific material, process, and economic constraints. By carefully weighing these factors, you can optimize your grinding circuit for peak performance, superior product quality, and lowest operating cost.

Ready to optimize your process? Always consult with your grinding media supplier. They can provide trial samples and technical data to help you make the most informed and profitable decision.