Discover the quartz sand ball mill – a high-efficiency grinding solution for glass, ceramics, and construction. Learn how it works, benefits, and how to choose the best one!

Introduction

Quartz sand is a crucial material in industries like glass manufacturing, ceramics, construction, and electronics. To achieve the desired fineness and purity, a quartz sand ball mill is often the preferred grinding equipment. This article explores the benefits, working principles, applications, and selection tips for quartz sand ball mills to help you make an informed decision.

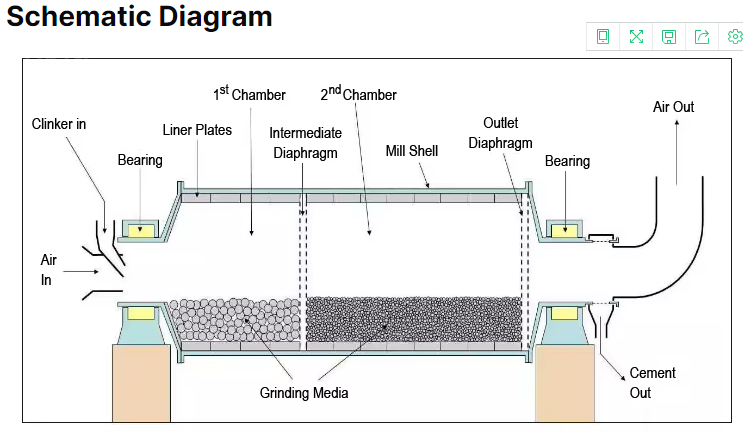

A quartz sand ball mill is a type of grinding machine used to grind quartz sand into fine powder. It consists of a rotating drum filled with grinding media (usually steel or ceramic balls) that crush and grind the quartz particles through impact and friction.

High grinding efficiency

Adjustable fineness (from coarse to ultra-fine powder)

Durable construction for long-term use

Suitable for both wet and dry grinding

Feeding: Raw quartz sand is fed into the ball mill through a feed hopper.

Grinding: The rotating drum causes the grinding media to collide with the quartz particles, breaking them down.

Discharge: The ground quartz powder is discharged through a screen or classifier, ensuring the desired particle size.

✅ High Efficiency: Achieves uniform particle size distribution.

✅ Versatility: Can be used for both dry and wet grinding processes.

✅ Cost-Effective: Low operational costs with high output.

✅ Durability: Robust construction ensures long service life.

✅ Wide Application: Suitable for industries like glass, ceramics, and foundry.

Glass Manufacturing: Produces fine quartz powder for high-quality glass.

Ceramics & Refractories: Ensures smooth texture in ceramic products.

Construction: Used in cement and concrete production.

Electronics: Provides ultra-pure quartz for semiconductor production.

When selecting a ball mill for quartz sand, consider:

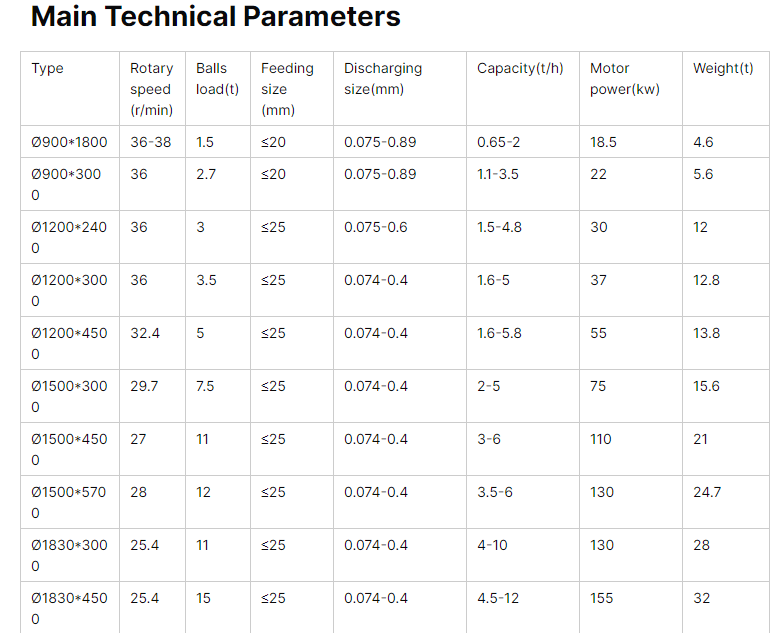

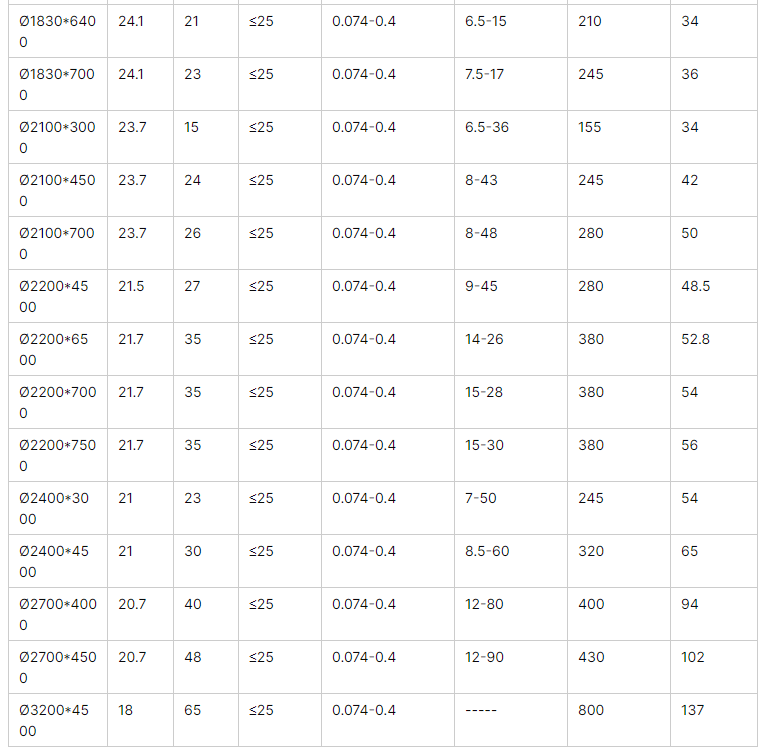

🔹 Capacity: Choose a mill that meets your production needs.

🔹 Grinding Media: Steel or ceramic balls, depending on purity requirements.

🔹 Particle Size: Ensure the mill can achieve your desired fineness.

🔹 Power Consumption: Opt for energy-efficient models.

🔹 Wet vs. Dry Grinding: Select based on your process requirements.

Regularly inspect and replace worn-out grinding media.

Lubricate moving parts to reduce friction.

Clean the mill to prevent contamination.

Monitor motor performance to avoid breakdowns.

A quartz sand ball mill is an essential tool for industries requiring finely ground quartz powder. Its efficiency, durability, and versatility make it a valuable investment. By selecting the right mill and maintaining it properly, you can enhance productivity and product quality.

Contact us today for expert recommendations and high-quality grinding solutions!