AAC is a kind of light cellular silicate products. Main material based on Silicon materials ( sand, fly ash,gangue contains silicon)and Calcium(cement and lime),mix with foaming agent (Aluminium powder), a fter batching, mixing, pouring,pre-curing,cutting,steam(autoclaved) and other process ,finally, get this light weight concrete products.

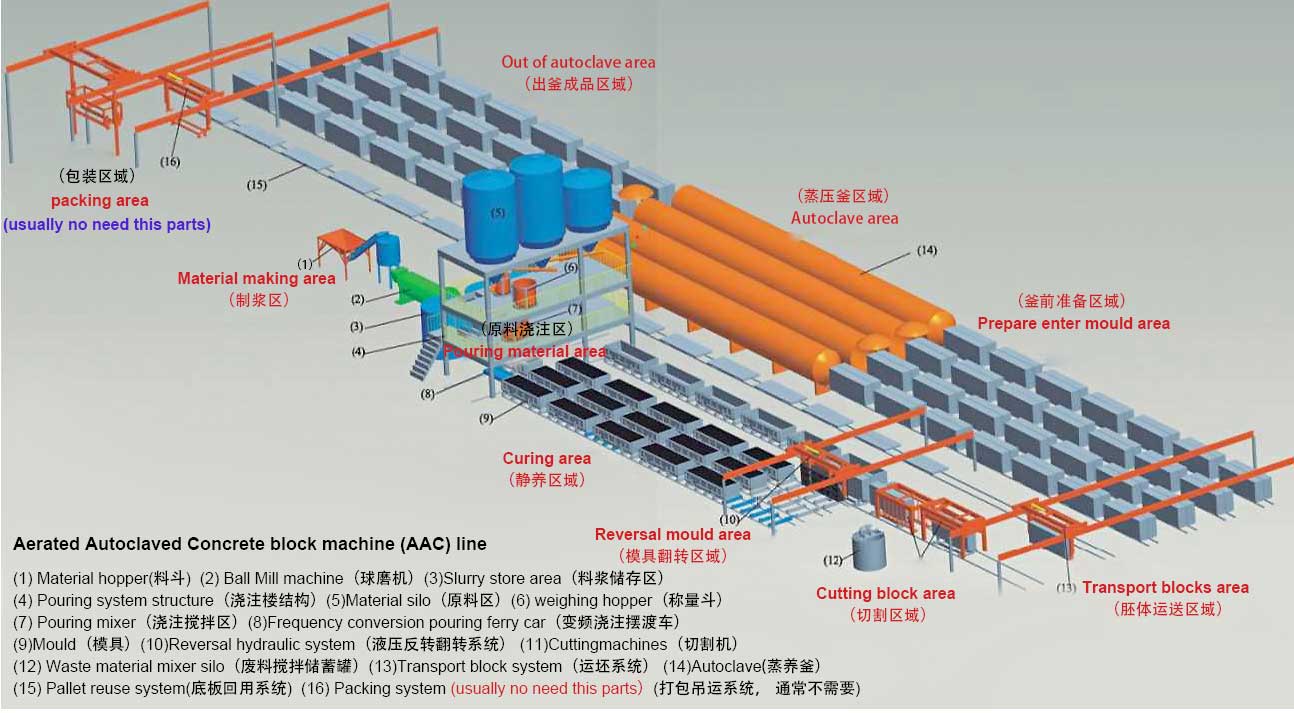

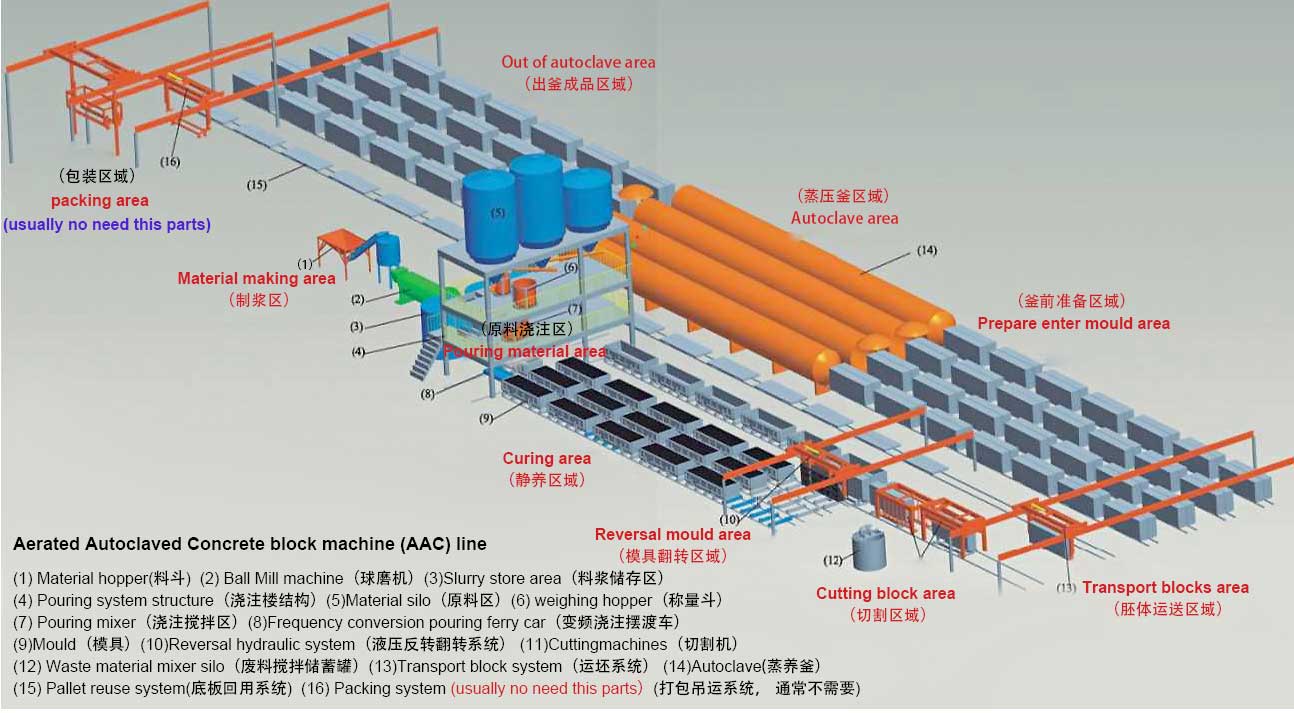

Aerated Autoclaved Concrete block machine (AAC) line:

(1)Material hopper (2)Ball Mill machine (3)Slurry store area (4)Pouring system structure

(5)Material silo (6)Weighing hopper (7)Pouring mixer (8)Frequency conversion pouring ferry car

(9)Mould (10)Reversal hydraulic system (11)Cutting machines (12) Waste material mixer silo

(13)Transport block system (14)Autoclave (15) Pallet reuse system

(16) Packing system (usually no need this parts)

Aerated block's precuring and cutting:

1.Ball mill 2.raw material silo 3.slurry storage tank 4.material scale 5.casting mixer 6.pouring system 7.Mould 8.Cutting Machine 9.prepare to enter the autoclave 10.Autoclave 11.boiler 12.Finished product

Why Choose Our AAC Block Machine Line?

✅ Fully Automated – Reduce labor costs & improve consistency

✅ High Output (50,000–300,000 m³/year) – Scalable for small to large plants

✅ Energy-Saving – Lower fuel consumption with advanced curing technology

✅ Eco-Friendly – Uses fly ash/recycled materials, zero waste

✅ Turnkey Service – From design to installation & worker training

Featured Machines in the Line:

Raw Material Processing (Ball mill, slurry mixer)

Batching & Mixing System (PLC-controlled accuracy)

Molding & Cutting (4D/6D cutting for precise block dimensions)

Autoclave Curing (High-pressure steam hardening)

Packaging & Stacking (Robotic or semi-auto options)

Applications of AAC Blocks

Applications of AAC Blocks

🏗 Construction – Walls, floors, roofs

🔥 Fire Resistance – Up to 4 hours (non-combustible)

❄️ Thermal Insulation – 3x better than clay bricks

🌊 Waterproof – Ideal for high-humidity areas

Customer Success Stories

"We increased production by 40% with their AAC line in Indonesia. The autoclave system cut energy costs by 30%!"

– Rajesh P., Project Manager

*"Their team delivered training and 24/7 remote support. Minimal downtime since 2021."*

– Maria L., Plant Owner, Malaysia

📅 Book a Free Consultation – Get a customized AAC plant layout & ROI analysis.

FAQs

Q: What’s the AAC block production cycle time?

A: ~8–12 hours (including autoclaving).

Q: Do you provide raw material sourcing guidance?

A: Yes! We help localize suppliers for lime, cement, and fly ash.

Q: What’s the warranty?

A: 2 years for core machinery, lifetime technical support.

Applications of AAC Blocks

Applications of AAC Blocks